Solving marine vibration challenges with real-life insight

When Area Sales Manager Andreas Videriksen Clemensen joined G&O Compensators four years ago, it was as a service technician. Today, he’s part of the sales team – with a special focus on retrofit projects. His background in hands-on installations gives him a unique edge when talking to customers around the world.

Andreas originally trained as an auto mechanic, and after several years travelling around Europe setting up exhibitions and working for DSB, maintaining trains, he joined GOMG in 2021 as a service technician.

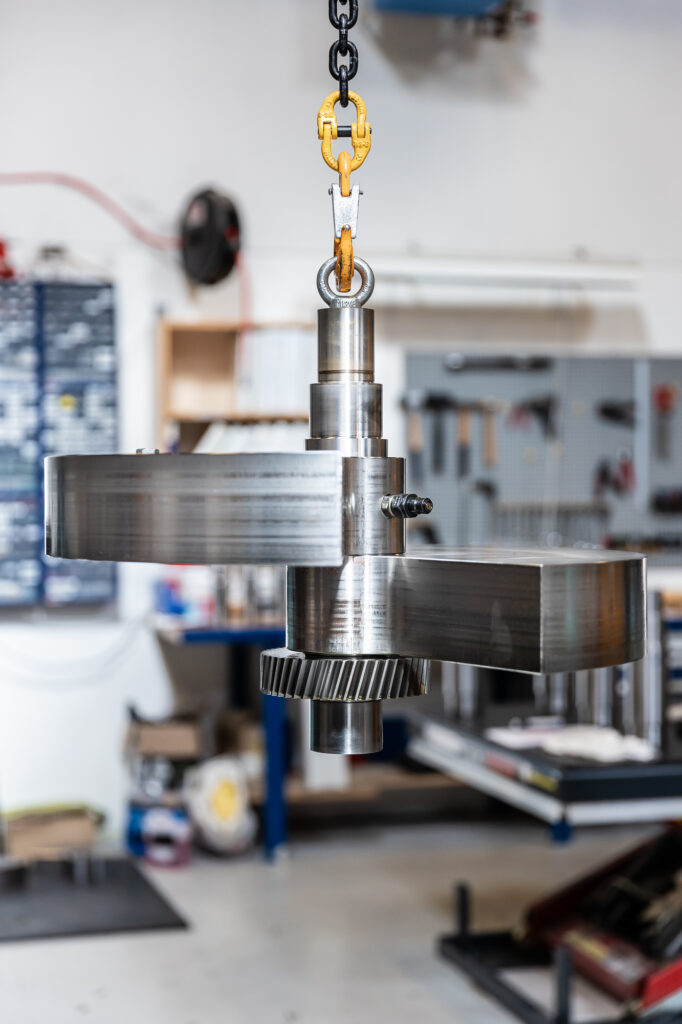

“For GOMG, I travelled around servicing, installing, and refurbishing compensators. I learned the ins and outs of our two main types – horizontal and vertical – and got to understand the real-world challenges our customers face. With larger and more powerful engines becoming the norm, vibration levels are rising. That’s where we come in,” Andreas says.

After three years on the road and harbours around the world, the opportunity came to shift into sales.

“My partner and I were starting a family, and I wanted something more stable. When a position opened in the sales team, I thought I might be able to use my product knowledge to support customers in a new way.”

A new rhythm at the office

The transition from fieldwork to a desk job wasn’t without challenges. “It’s a different pace. In hands-on work, you just go out and solve things. In sales, you need to be more patient and structured. That took some getting used to – but I really enjoy it.”

He started in the sales team in January 2025, taking over responsibility for all retrofit enquiries. “Now I talk to customers from all over the world. One of the first projects I managed actually started three years ago when I was still in the field. It finally landed just a few months ago – and now we’re preparing to carry out the installation while the vessel is at sea, together with people from the newest part of our group, Global Boiler Services.”

Growing interest in retrofit solutions

Retrofit is a growing market, says Andreas. “Engines are getting bigger, which means more vibration. The market is regulated by new ISO standards coming into play, which creates challenges and opportunities. There is also a growing understanding that ship vibrations increase main engine wear and shorten the lifespan of other critical components, such as electronics, – and we can document that wear and tear and calculate return on investment together with our customers. We also help customers deal with critical RPMs and the challenges that come with switching to alternative fuels, which often change the vibration patterns. The installation of a compensator means that a vessel can utilise the full RPM range without critical vibration. Without a critical RPM range, the vessel can stay in the most fuel and emission-effective RPM during different load and weather conditions.”

Speaking the same language as the customer

Andreas’s background as a technician helps him connect with customers, especially the technical management teams who often have seagoing experience themselves.

“They know the ships and the workflows – and so do I. I’ve felt the vibrations they’re describing, and I have worked with them in the engine rooms. That creates a kind of trust and understanding you can’t fake.”

Today, Andreas still travels for work, but much less than before. “I used to be away 140 days a year. Now it’s more like 30 to 50 – and that suits my life better at this stage.”

As he prepares to go on paternity leave, Andreas reflects on the support he’s had. “I’ve had great mentoring and the best support in my shift in career within GOMG.”

Contact us for expert advice on vibration challenges

Contact Andreas or other members of our team to get expert advice on virbations issues.