Horizontal Compensator

Smoother operation with G&O Compensators

Benefits of the horizontal compensator

G&O Compensator’ horizontal compensators effectively eliminate vibrations and forces arising from guide force H moments – the horizontal rocking movements of the top of the engine. Unlike conventional countermeasures that merely transfer vibrations elsewhere on the vessel, our horizontal compensator addresses the problem at its source.

- Mounted directly on the main engine gallery to neutralise horizontal vibrations at the source.

- Reduces the need for extensive steel reinforcements, leading to lower construction costs and lighter ship designs.

- Enhances operational flexibility by enabling sailing at optimal RPM without compromising crew comfort or safety.

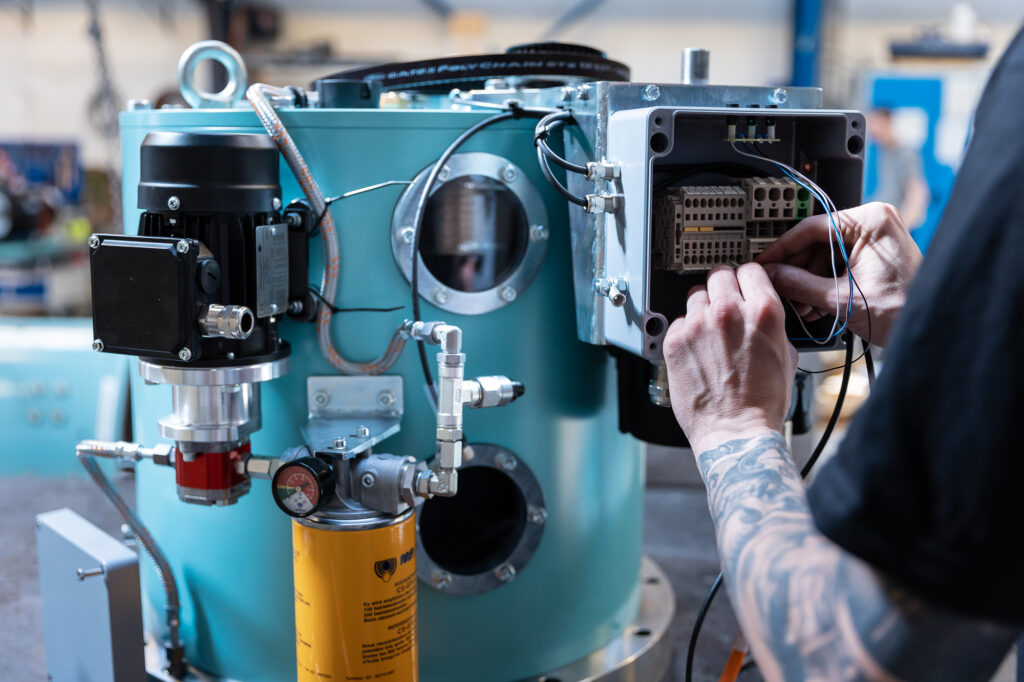

Technical features

The G&O Horizontal Compensator is specifically designed to eliminate lateral vibrations caused by two-stroke main engines. It generates a precise counterforce through active negative interference, automatically adjusting in real time to the required magnitude (0–100%) and direction (0–360°) with an angular accuracy of ±1°. This ensures targeted and continuous suppression of horizontal oscillations that typically occur within specific RPM ranges or under varying load conditions.

By neutralising vibrations at the source, the system protects adjacent structures and components from excessive fatigue, reduces maintenance demands, and contributes to smoother, more stable engine operation. The result is improved vessel performance, extended equipment lifespan, and significantly enhanced working conditions for the crew on board.

Easy installation and operation

- Delivered as a complete turnkey solution including cables, brackets, and system components.

- Quick installation without disrupting vessel operations.

- Fully automatic operation with no manual adjustment needed after commissioning.

- Recommended time Between Overhaul (MTBO): 20,000 running hours.

Experience a significant improvement in both operational safety and crew well-being with a G&O Horisontal Compensator.

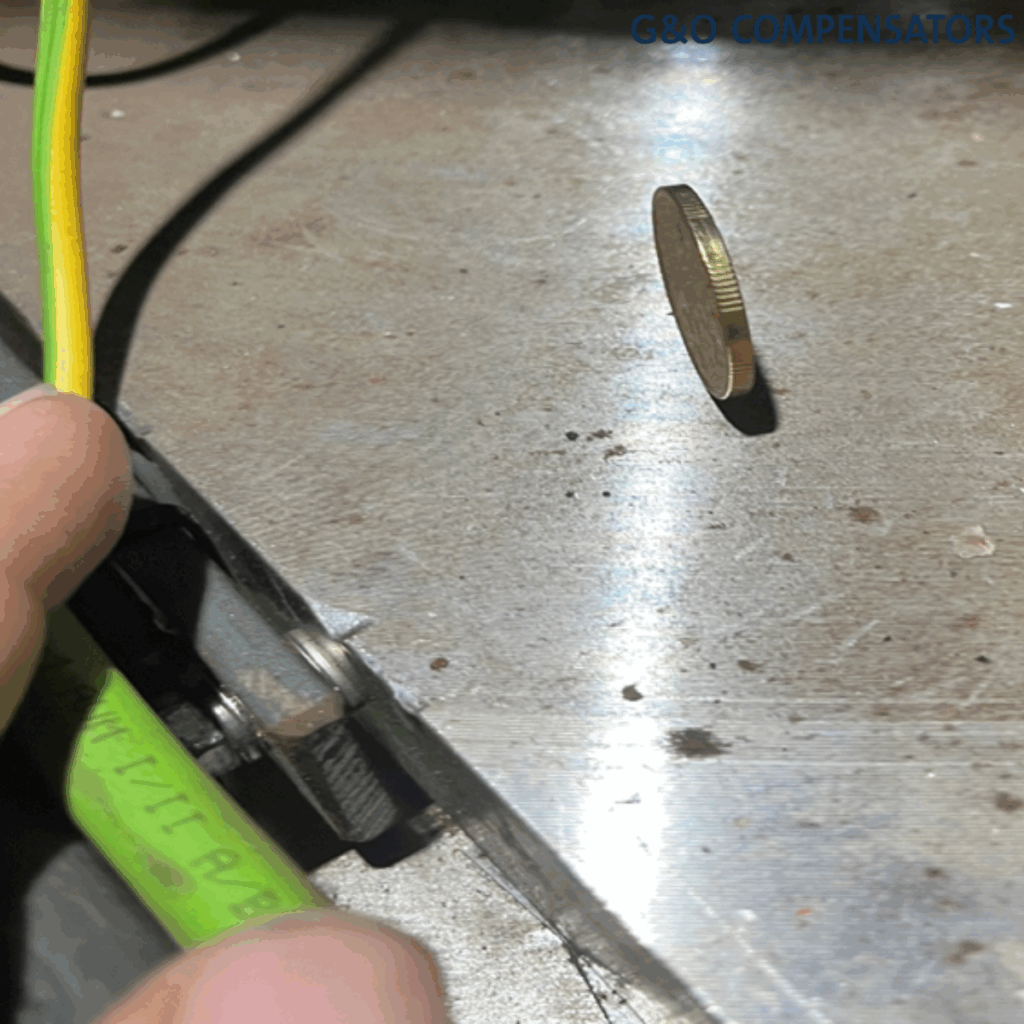

Horizontal compensator case: Coin-solid proof

A vessel operating with excessive horizontal engine vibrations—especially around 92 RPM—faced serious challenges related to structural fatigue, electrical system stress, and onboard comfort.

After installing a G&O horizontal compensator, the results were immediate and measurable:

- Horizontal vibrations in the 6th order dropped by 89.08%

- Stress levels on both hull and equipment were dramatically reduced

- Onboard comfort improved so noticeably that a 20 DKK coin could stand upright in front of the active compensator

FAQ – Horizontal compensator

Get an answer to some of the most frequently asked questions about our horizontal compensators.

What vibration levels can be expected after installation?

In documented cases, the horizontal compensator has reduced vibration levels by up to 90%, including 6th-order vibrations that typically occur at critical RPM ranges.

How is the compensator installed?

Installation is typically carried out during scheduled docking or port stay. The system is designed for integration with minimal structural modifications and includes final calibration via sea trial testing to ensure optimal performance.

Does it require ongoing maintenance?

The compensator is built for long-term durability with low maintenance requirements. Regular inspections are recommended as part of routine engine room maintenance, and full refurbishment can be offered through our Exchange Service.

Can it be retrofitted to existing vessels?

Yes. The horizontal compensator is frequently installed as a retrofit solution. G&O provides full vibration analysis, engineering adaptation, and installation support to ensure seamless integration with the existing engine configuration.

What power and control systems are used?

The system includes a closed-loop servo control with integrated sensors, capable of adjusting the force vector automatically. All units are tested and calibrated prior to delivery and during commissioning on board.

What is the expected return on investment (ROI)?

Shipowners typically experience ROI through reduced maintenance costs, improved operational efficiency, and fewer vibration-related failures. ROI varies depending on vessel type and vibration profile but is often achieved within 1–2 years.

Contact our vibration experts

Get in touch with our team to explore how the G&O Horizontal Compensator can improve your vessel’s stability, protect your structure, and enhance crew comfort.