G&O Compensators

Vertical Compensator

Eliminate vertical vibrations for maximum stability

Benefits of the vertical compensator

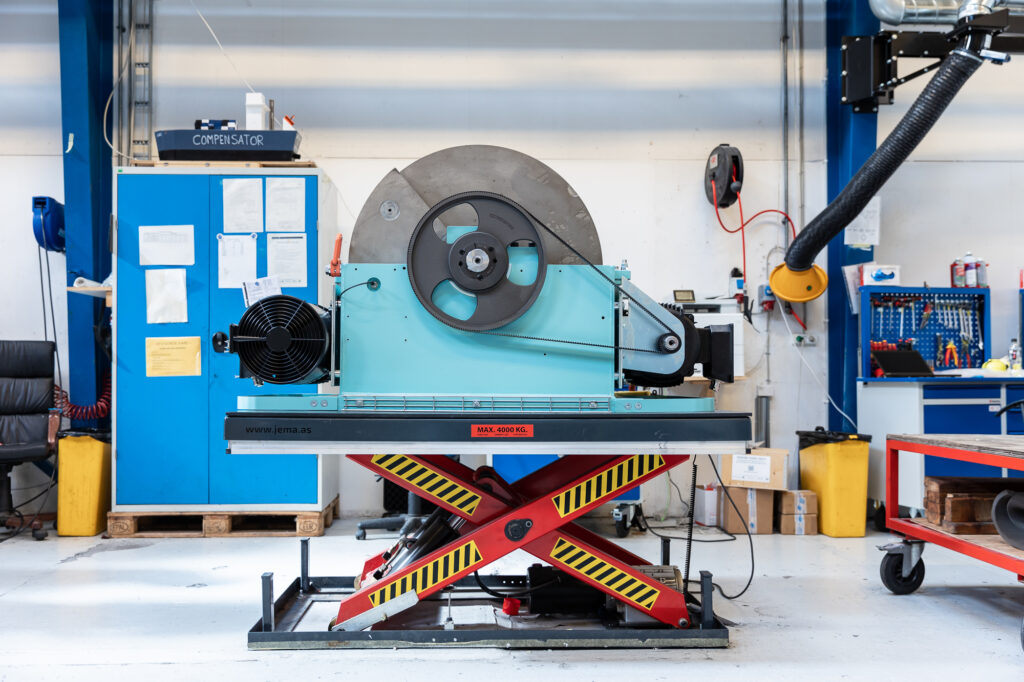

G&O Compensators’ vertical compensators are engineered to eliminate vertical vibrations caused by second-order external moments in ships with large two-stroke engines. Traditional solutions like heavy, built-in flyweights offer only partial effectiveness. In contrast, our vertical compensator provides a precise counterforce that significantly reduces vibrations, protecting the hull, piping systems, and other critical equipment.

- Typically installed in the steering gear room, where the distance from the engine creates an effective lever arm, enabling the use of a compact unit.

- Prevents vertical vibrations from propagating through the hull, safeguarding vital components and enhancing crew comfort.

- Reduces or eliminates the need for heavy steel reinforcements, lowering vessel weight and construction costs.

How the Vertical Compensator works

This short 2D animation illustrates the working principle and onboard placement of our vertical vibration compensator.

Designed to eliminate harmful vertical vibrations from two-stroke marine engines, the compensator is typically installed in critical piping systems to protect against stress, fatigue, and resonance.

Tested for extreme marine conditions, it is trusted by shipowners worldwide to ensure long-term structural integrity and vessel performance.

Technical features

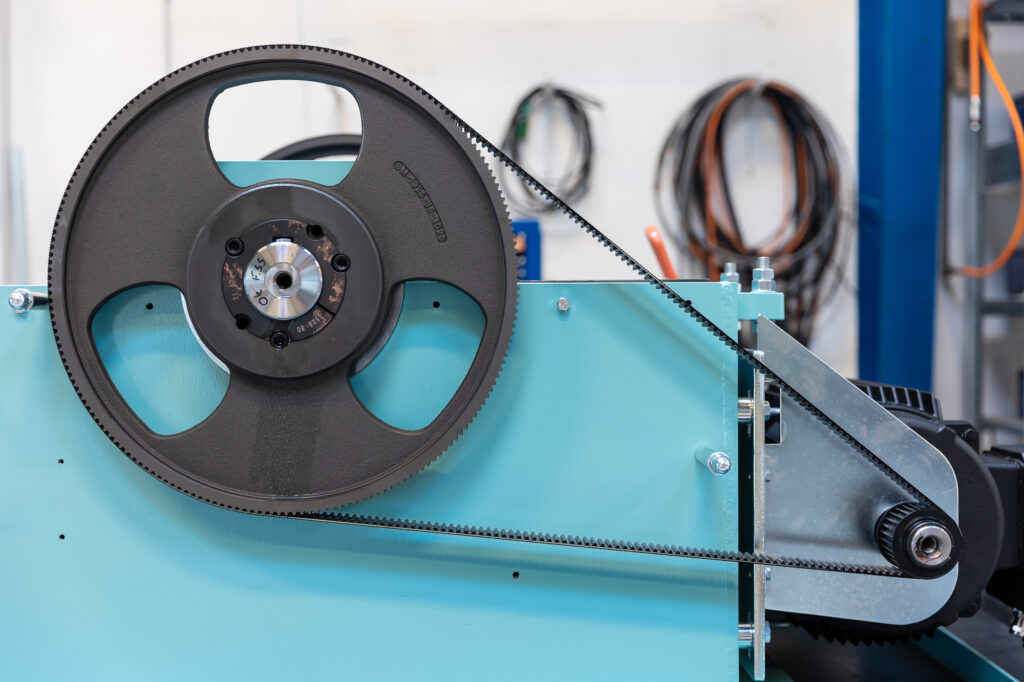

The vertical compensator neutralises engine-induced vibrations by generating a precisely timed counterforce. Controlled by a synchronising unit, high-torque electric motors, and a real-time RPM detection system, it ensures accurate phase and frequency adjustment under all load conditions.

Built for maritime performance, the sealed unit integrates vibration sensors and closed-loop control to deliver up to 80% vibration reduction. Designed for easy retrofit or newbuild installation, it requires minimal structural modification and supports integration with vessel monitoring systems for predictive maintenance.

Easy installation and operation

- Can be retrofitted without interrupting vessel operations.

- Operates automatically with no need for crew intervention.

- Recommended time between overhaul (MTBO): 40,000 running hours.

Gain control of vibrations and create a safer, more stable onboard environment with a G&O Vertical Compensator.

FAQ – Vertical Compensators

Frequently asked question and answers about vertical compensators.

What does a vertical vibration compensator do?

A vertical compensator eliminates harmful engine-induced vibrations by generating an active counterforce. It targets vibrations in the vertical plane—typically from two-stroke main engines—and reduces stress on structures, machinery, and crew.

How much vibration reduction can I expect?

G&O Vertical Compensators can reduce vertical vibration levels by up to 80%, depending on the vessel type, engine configuration, and operating profile.

Which vessels benefit from a vertical compensator?

They are ideal for container ships, bulk carriers, and tankers operating with two-stroke engines. Vessels experiencing excessive vibration at certain RPM ranges especially during slow steaming—will see significant operational and comfort improvements.

Is it suitable for retrofit?

Yes. Our compensators are fully retrofittable, with minimal structural modifications required. Installation is typically completed during scheduled docking and includes sea trial testing and calibration.

Can it be integrated with our monitoring systems?

Yes. The system supports integration with shipboard condition monitoring tools, enabling vibration logging, performance tracking, and predictive maintenance.

What maintenance is required?

The compensator is designed for long service intervals, and our Exchange Concept allows for fast replacement and refurbishment with minimal downtime.

Contact our vibration experts

Talk to our experts about how a G&O Vertical Compensator can improve your vessel’s performance, reduce wear and ensure a safer working environment for your crew.