The vibration-free engines are here

For shipbuilders, vibrations have traditionally been treated as a natural consequence of Newtonian physics, rotational and oscillating forces. The response has been to work around the issue through overengineering: more steel, more cylinders, heavier structures, and restrictions on certain RPM levels. But what if there were a way to eliminate the source of the problem entirely?

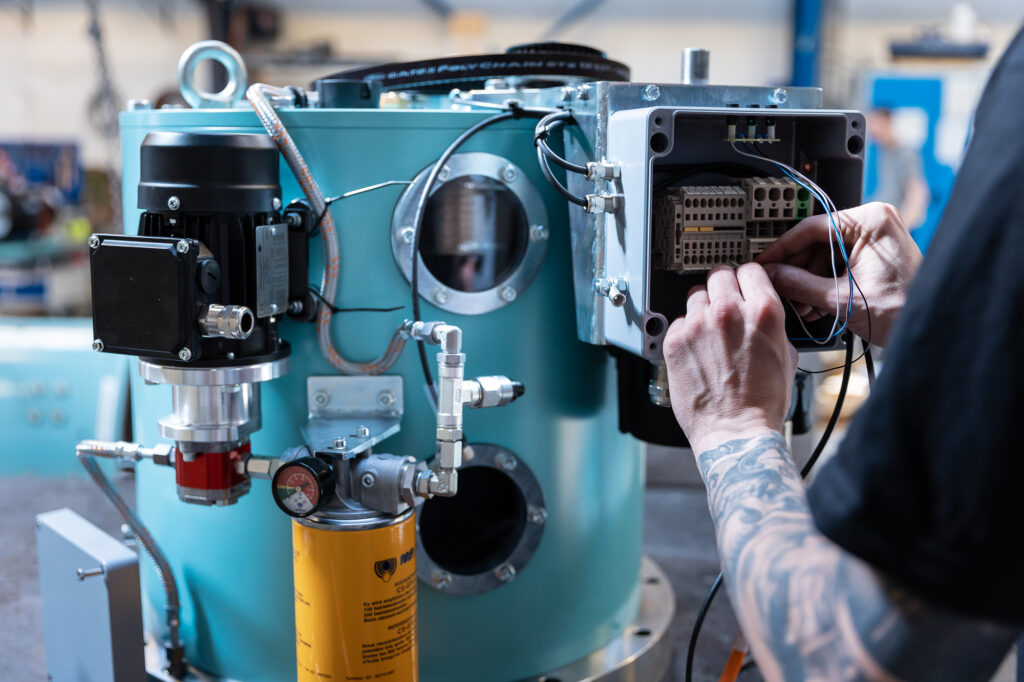

G&O Compensators now offers shipowners, shipbuilders, and engine designers a proven and highly effective solution – compensators that enable a vibration-free propulsion system as a core component of newbuild projects.

“By integrating our solution from the start, we remove a major uncertainty from the entire design equation. This allows for more flexible design, freedom of operation, and less wear and tear. We call it the moment-free engine,” says Jens Ulrik Nielsen, Head of Sales at G&O Compensators.

A conservative industry, with room for change

The shipping industry is, by nature, risk-averse – and understandably so. Vibration-related issues can affect both comfort and safety, and most vessels are still built to tolerate them through reinforcement and operational limitations. But this also comes at a cost: heavier ships, reduced efficiency, and inflexible operating profiles.

“The shipping industry knows the problem exists. Many have done complex simulations and built around known vibration zones. But it’s still a compromise. Our message is: it doesn’t have to be that way. There is now a mechanical solution that tackles the root cause,” says Jens Ulrik Nielsen

Simpler calculations, leaner designs

By neutralising the forces and moments created by large two-stroke engines, compensators remove the need for over dimensioning in key parts of the vessel. The result is a more streamlined design, reduced steel consumption, and a lighter ship.

“Think of it as the ultimate steel-saver, if you can avoid using excess material just to manage vibration risk, you improve both CAPEX and OPEX. And you reduce emissions from day one,” Jens Ulrik Nielsen says.

The benefits also extend to engine configuration. Compensators allow designers to downsize the engine complexity – for instance, installing a larger bore 6-cylinder engine where an 8-cylinder might otherwise be required. Fewer cylinders and larger bore mean lower maintenance and better fuel economy, while unrestricted RPM operation gives operators far greater flexibility when it comes to choice of fuel and operations.

Built-in reliability from the beginning

The adoption of compensators is already gaining traction in complex ship segments. “We supply to gas carriers that use eight compensators on a single vessel,” says Jens Ulrik Nielsen.

And with dual-fuel engines becoming increasingly common, compensators offer another layer of reliability. As engine behaviour changes depending on the fuel type, vibration characteristics shift, and compensators help maintain optimal performance across a broader range of RPM.

A small investment, a major upgrade

Compared to the overall cost of the engine room, installing compensators during newbuild is a minor investment. But the long-term benefits – in design freedom, operational flexibility, and fuel savings – are significant.

“Too often, people only act when they experience vibration issues. Our approach is initiative-taking. We eliminate the cause from the beginning. The technology is here now – and no matter how you calculate it, the economics are clear. Installing compensators during the newbuild phase delivers a positive return. Whether the focus is on reduced steel weight, freedom of navigation, simplified design, or improved fuel efficiency, the overall lifecycle cost of the vessel is significantly lowered,” says Jens Ulrik Nielsen.

If you have any questions, don’t hesitate to contact us.